By Andrea McKenzie and Coro Strandberg

In the world of precise technical specifications, the International Standards Organization (ISO) has been chugging away for seventy-plus years, facilitating international trade by providing common standards between nations. Since its founding in 1947, it has been designing standards for the industrial economy. Accordingly, standards reflect the take-make-waste economic model that underpins our disposable culture.

With the recent publication of ISO’s Sustainable Procurement Standard, we are seeing standards evolve to enable a more circular economy. The sustainable purchasing guide provides a roadmap for buying goods and services with sustainability in mind, and advises buyers on procurement strategies that advance circular supplies. In the guide, ISO defines the circular economy as “an economy that is restorative and regenerative by design, which aims to keep products, components and materials at their highest utility and value at all times.”

While the Sustainable Procurement Standard is a good start, there are more than 22,000 ISO standards in existence. To re-engineer our linear economy to a circular economy, each ISO standard should be reviewed with an eye to the opportunities for incorporating circularity principles.

Recently, we collaborated on an opportunity to review ISO’s Product Use Instructions Guide. This standard – last updated in 2012 – gives guidance to product designers, manufacturers and importers on the best way to inform customers and users on how to correctly and safely use their products. It covers text, symbols, illustrations and audible information about the product, its packaging and accompanying materials. The standard is currently under review by ISO’s Committee on Consumer Policy.

Current Guide emphasizes linear economy model

The first observation during our review was that the Product Use Instructions Guide – only six years young – recommended destruction and disposal of unwanted products, and to a lesser extent recycling, while overlooking the important circular concepts of repair and reuse. There was no reference to “product reuse” as an option for managing unwanted products, meaning that the current Guide reinforces the linear economic paradigm by assuming only a single life cycle for a product.

Prescribing destruction and a single life cycle as the default for managing unwanted products perpetuates the need to consume virgin resources, increasing the risk of global resource scarcity. As a start, we recommend that product use instructions educate users about how to manage broken and unwanted products, and emphasize options for reuse, return through take-back programs, and recycling ahead of disposal and destruction. To maximize recyclability, product parts should also be labeled to facilitate disassembly for source-separated material recovery.

In addition to educating consumers about how to manage unwanted and broken products in a circular economy, product use instructions can enable circular practices during the useful life of the product. First, instructions should inform consumers how to correctly use the product to avoid or minimize any harmful ecological impact. Next, instructions should enable users to maximize the useful life of the product by including information about correct usage, maintenance, repair, and replacement parts. Labeling product parts can help to facilitate maintenance and repair and repair instructions should be accessible, durable and/or available for replacement.

Incorporating these circular concepts into ISO’s Product Use Instructions Guide would replace the linear take-make-waste assumption with a more circular model.

Transferring circular skills to consumers

Product use instructions are an ideal opportunity to teach consumers circular skills and know-how. To that end, we propose these Circular Economy Principles for product use instructions:

- Enable consumers to make purchase decisions equipped with information about the relative ecological impacts, useful product life and repairability of one product choice over another.

- Educate consumers about how to use and maintain the product correctly to avoid or minimize harm to the environment.

- Enable consumers to extend the product’s useful lifespan by providing correct usage, maintenance and repair instructions, and labeling product parts.

- Make the instructions accessible, durable, available for replacement, and complete with information about how to obtain replacement parts.

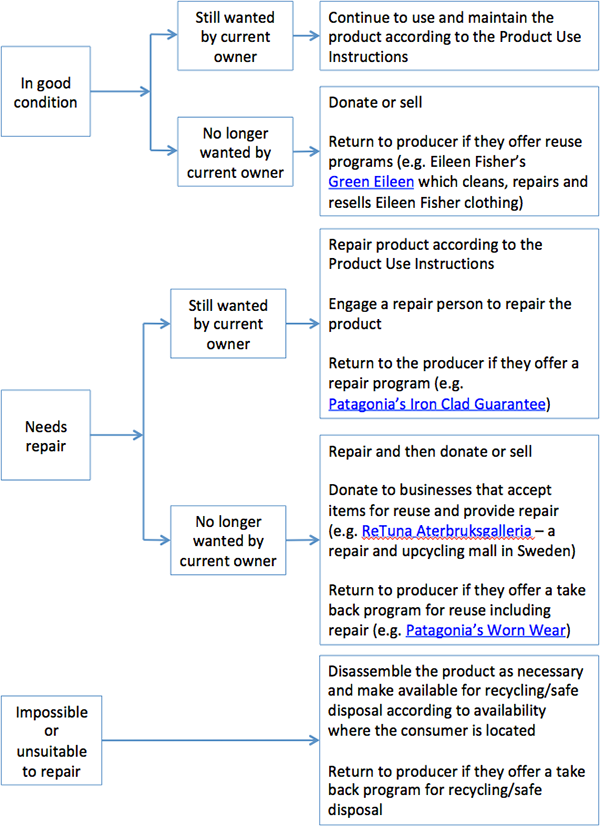

- Educate the consumer about how to manage the product when they no longer want it, or when it’s broken – i.e. the product should be reused if in good condition, repaired if broken, and directed towards the appropriate recycling mechanisms if unsuitable for reuse or impossible to repair (as shown in the decision matrix below).

- Instruct consumers how to disassemble products and label product parts to facilitate source-separated material recovery.

A sample decision matrix for managing unwanted and broken products is presented below. It may be noted that additional parameters can be expected to affect the product user’s actions, such as: cost of repair relative to the cost of buying new; level of comfort in performing do-it-yourself maintenance and repair tasks; convenience and availability of repair services; duration of repair relative to when the product needs to be used; etc. Nonetheless, these criteria can serve as a framework to underpin a more detailed decision matrix.

Circular Decision Matrix for Managing Broken and Unwanted Products

We have submitted these circular concepts to the ISO committee that is currently updating the standard and await its decision.

Circular consumption requires others to play their part

Circular consumption and product management is not achievable via product use instructions alone. The information provided by product use instructions is a reflection of the product design itself. For example, it doesn’t make sense to provide repair instructions if the product has not been designed for do-it-yourself repair. In addition to making repair possible, circular product design can include aiming to extend the product’s useful life, minimize environmental impact, and/or allow disassembly for source-separated recovery.

Some designers, manufacturers and retailers are leading the way by designing circular products and developing circular business models, but the shift to a circular economy paradigm can also be supported by incorporating circular concepts into ISO standards relevant to product design and manufacturing. Since ISO standards are continually reviewed and updated, this approach is ripe for action. We look forward to a future where circularity is the assumption, and an industry standard.

Andrea McKenzie is a Zero Waste Project Engineer for the City of Vancouver. Coro Strandberg is a leading sustainability consultant, and member of the City of Vancouver’s Zero Waste 2040 Advisory Panel.